Our products

With the Mulco belt-pilot on the direct path to the optimum design solution for your PU timing belt drive

BRECOFLEX® and CONTI® SYNCHROFLEX continuous timing belts without tension member interruption can be used for any power transmission application.

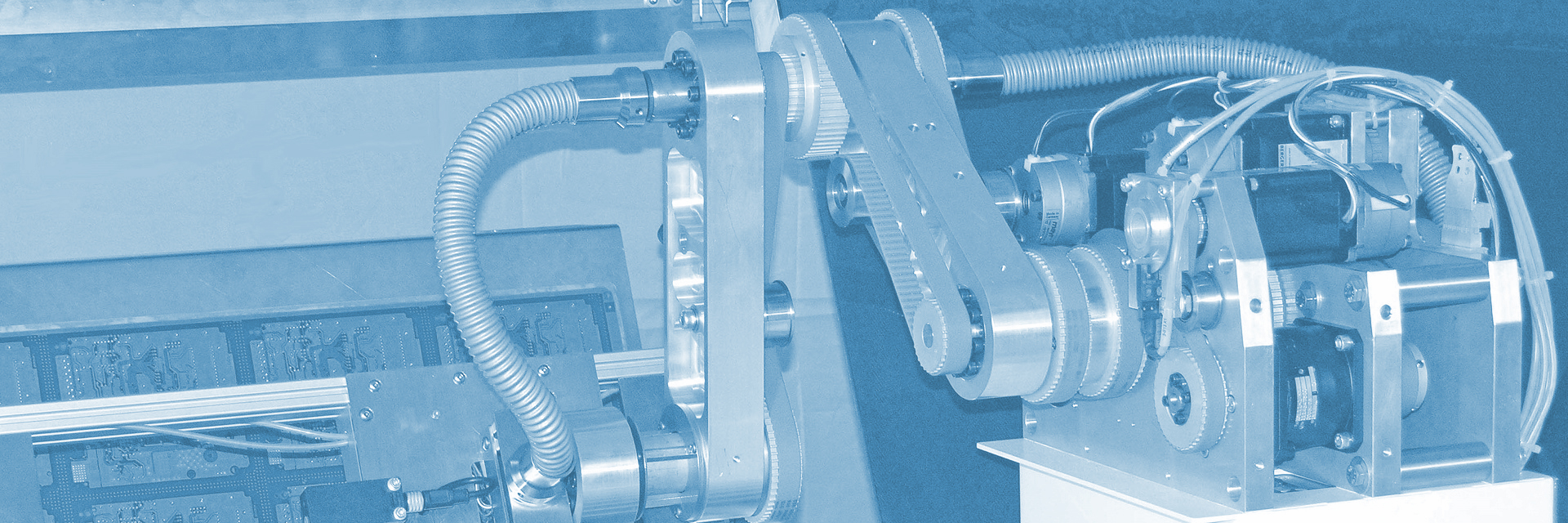

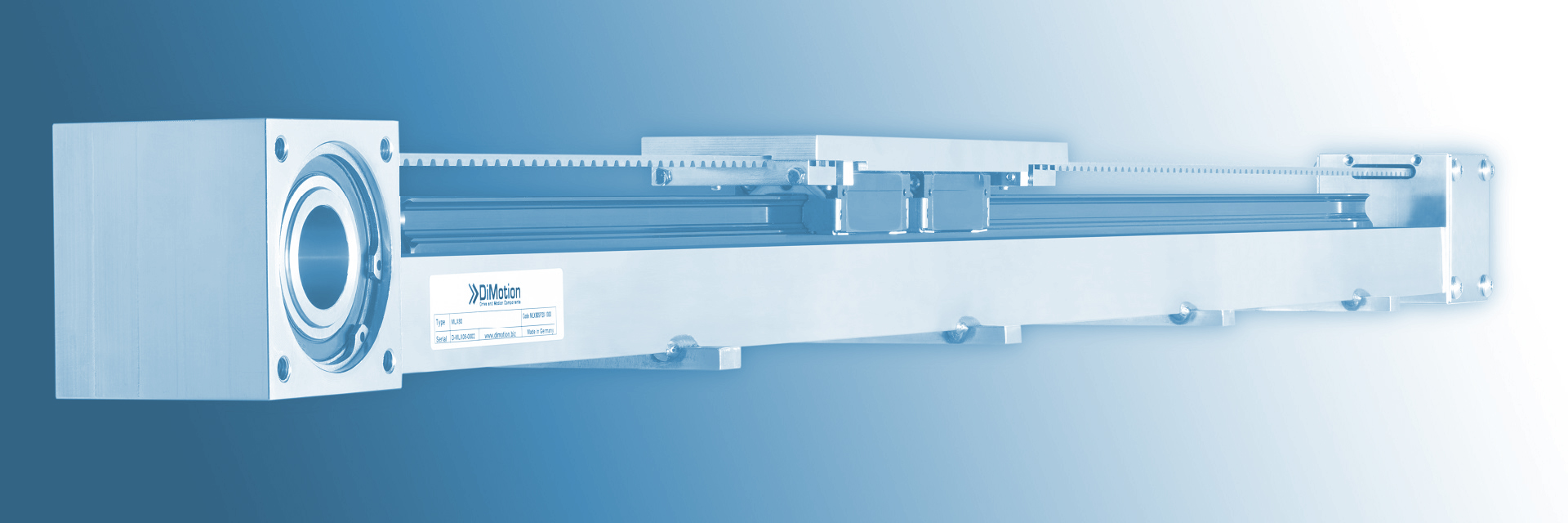

Rotary movements are converted into linear movements by linear transmissions. For linear transmissions BRECO® and CONTI® polyurethane timing belts are primarily supplied by the metre.

For conveying technology, continuously welded timing belts are used to cover any centre distance. Coated polyurethane timing belts or belts equipped with profiles are used for special transport tasks.

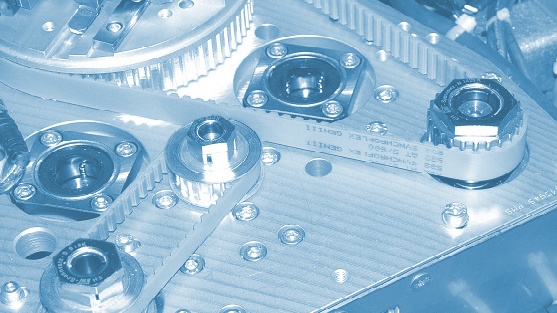

Here you can find our extensive product range consisting of timing pulleys and components such as clamp plates, tension plates, tensioners and many other products.

Interesting facts

Specifically developed for high-performance drives and traction drives requiring a high degree of stiffness, the innovative BRECOFLEXmove polyurethane timing belt can transmit up to 30% higher peripheral force. The new AT8 pitch is now available for the "move" product line, also here in the Mulco belt-pilot in the power transmission calculation, as a CAD download and in the product catalogue.

The best possible solution for every product down to the smallest technical detail - the CONTI® SYNCHROFLEX GEN III for the AT and ATP series meets this requirement by using a bifilar tension member arrangement and with a higher packing density. The high-performance polyurethane used is characterised by significantly higher performance values.

BRECO®, BRECOFLEX® and CONTI® SYNCHROFLEX timing belts are manufactured from wear resistant polyurethane and high tensile steel cord tension members. Polyurethane timing belts have a very high longitudinal stiffness and no post-elongation of the tension members is to be expected in continuous operation.

BRECO® and BRECOFLEX® PU timing belts are produced using the extrusion process. CONTI® SYNCHROFLEX PU timing belts are manufactured using the casting process.

Polyurethane timing belts are used in a wide range of applications in power technology, linear technology and transport technology. Timing belts suitable for operation at low temperatures, in clean rooms and also in the food industry can be produced with different polyurethane compounds.