Pre-tension force

Pre-tension is intended to guarantee a minimum tensioning force at the slack span side to ensure smooth tooth meshing into the driven pulley.

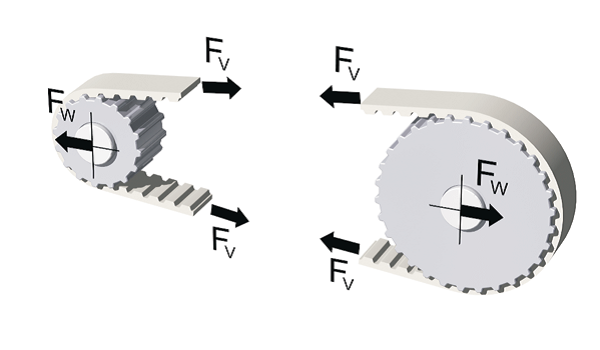

Generally, the pre-tension should only be set as high as necessary. The necessary pre-tension force of the spans FV depends on the max. circumferencial force FU, the belt length LB (number of teeth ZB) and the drive configuration.

The recommendations shown in the table refer to the pre-tension force setting per span.

| Drive configuration | Pre-tension force of each individual span |

|---|---|

| Two-shaft drive ZB < 60 | Fv = 1/3 Fu |

| Two-shaft drive 60 = ZB < 150 | Fv = 1/2 Fu |

| Two-shaft drive ZB > 150 | Fv = 2/3 Fu |

| Multiple-shaft drive L load span = L slack span side | Fv = Fu |

| Multiple-shaft drive L load span > L slack span side | Fv > Fu |

| Linear drive | Fv = Fu |

In every case, the tension cord strength is the top limit of the span load. Take into consideration that especially with multi-shaft and linear drives, an addition of the pre-tension force and the circumferencial force in relation to the load span force is to be expected.

Influence variables

Stiffness of the belt

Friction forces created by the interaction of the tooth mesh (especially at the slack span) intensify the span forces, which in turn increase the degree of elongation.. This influence may lead to the slack span tooth mesh butting against the driven pulley, thereby causing the belt to jump.< /br> Elongation being directly depending on the belt stiffness, the high stiffness of the steel cord tension members permits a comparably low pre-tension.

Circumferencial force

The circumferential force acts in proportion to the elongation of the load span, i.e. excessive slackening of the slack span can be counter-acted by a pre-tension matched to the circumferential force.

Belt length

Belt elongation resulting from the effect of the circumferential force and the friction forces is also approximately in proportion to the belt length. Therefore, the tendency of running up or jumping is considerably influenced by the belt length. Even under high circumferential forces with the resulting friction forces, a very short timing belt will elongate to only a small degree, so that even when subject to low pre-tension forces there will be no danger of running up or jumping of teeth. On the contrary, with short timing belts circumferential deviations of the pulleys could cause heavy pre-tension fluctuations and, as a result, extreme peak values.

Proportion of the span lengths

Especially with multi-shaft drives the load span is often markedly longer than the slack span side. For this reason, a slight elongation of the load span results in a very unfavourable slack on the span side. Therefore, the pre-tension force of spans of such gearings should be higher than the circumferencial force.

Precise transmission of movement

There is a high transmission accuracy possible in the reverse operation with BRECO®, BRECOFLEX® and CONTI® SYNCHROFLEX polyurethane timing belts , when the span pre-tension forces are selected in the same size of the circumferencial force.

Consequences of faulty pre-tension setting:

too low pre-tension

- the teeth of the slack span side run up on or override the teeth of the driven pulley

- Wear on the faces caused by the friction force during meshing

- Forced breakage by excessive elongation due to full overriding

excessive pre-tension

- high bearing load of the shafts

- Reduction of the transmissionable power

- Wear and tear at the belt tooth

Measuring with frequency measuring meter

The intrinsic frequency of a vibrating belt span can be measured by means of various Mulco belt tension measuring meters. The pre-tension force of the span can be calculated from the measured intrinsic frequency:

\[F_V = {4 \cdot m \cdot l_T^2\cdot f^2}\]

The corresponding intrinsic frequency can be calculated, if the pre-tension is preset:

\[f= {\sqrt{F_V \over 4 \cdot m \cdot l_T^2}}\]

f: Frequency of the variations in Hertz

m: Mass of the belt per meter length in kg/m

l: drum span subject to vibration in m

Fv: Span force in N