mechanical rework

BRECO®, BRECOFLEX® and CONTI® SYNCHROFLEX SYNCHROFLEX polyurethane timing belts can be mechanically reworked to meet special functional features. Timing belts with a thick backing are especially suited for mechanical rework

- BRECO®, BRECOFLEX®: Version T, type series DR and coatings/coverings

- CONTI® SYNCHROFLEX: Version FA and coatings/coverings

They offer further reaching design possibilities for the designer. Please note that the flexibility of timing belts with a thicker back is reduced, therefore requiring larger pulley diameters. Belt flexibility can be improved by cross grooving or incisions.

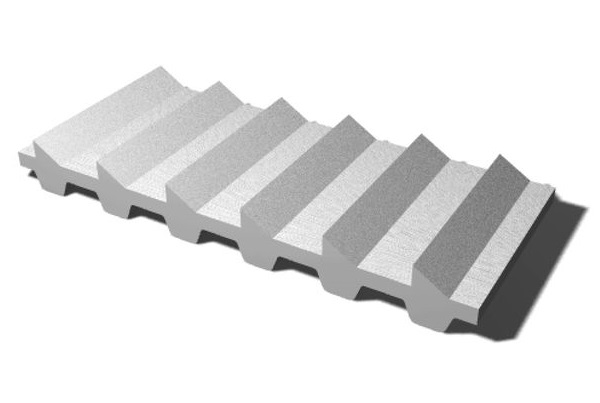

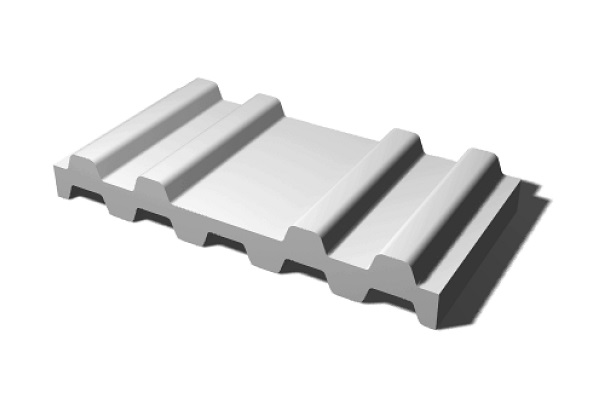

Back cross milling

Cross grooves on the belt back enhance the flexibility of the belt. Milled grooves are, in as much as they are possible from the technical feasibility point of view, used to improve safe loading and secure positioning of the products on the belts.

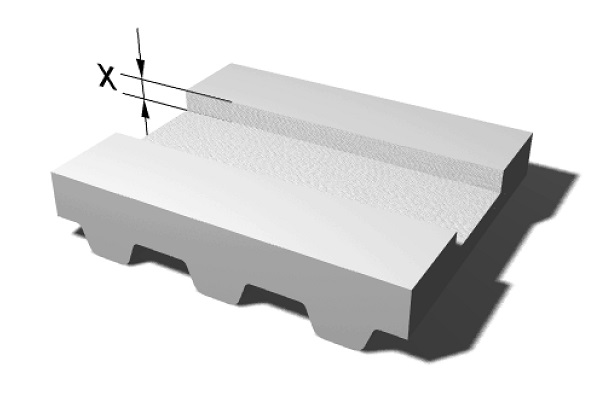

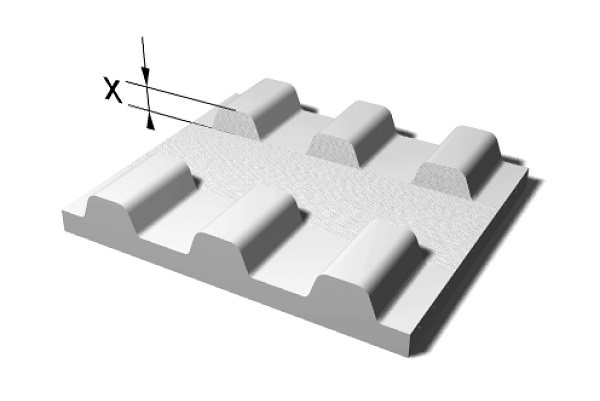

Back longitudinal milling

Independent on the belt pitch, the belt back shaping offers a wide range of design variants for customised solutions. In this manner, belt guiding can be achieved by a trapezoidal back profile, or a round section supported and moved by means of a prism shaped cross section. Dimensions are to be indicated as depth measure x in relation to the belt back.

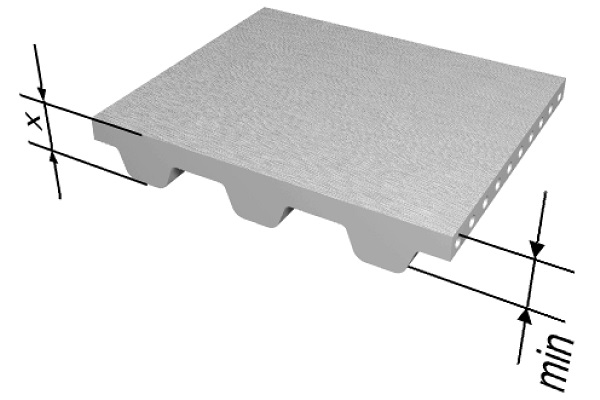

Back grinding

The backs of all BRECOFLEX® polyurethane timing belts are ground. For reasons of precision or in order to obtain a roughened surface, all other timing belts of the Continental and BRECO delivery range can be ground. Here the overall thickness x must not fall below a minimum thickness, otherwise the tension members could be damaged.

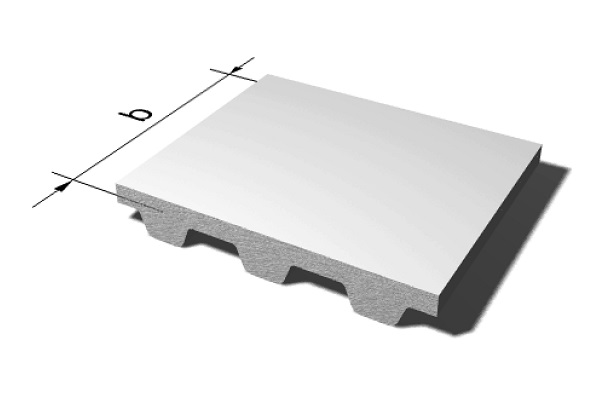

Edge grinding

Particularly accurate belt width tolerances can be achieved by grinding the belt edges. Edge grinding might become necessary with BRECO® polyurethane timing belts running on bed plates.

Removing individual teeth

The removal of individual teeth or groups of teeth is possible and practical due to the high dimensional precision meshing, when the remaining teeth are to serve as precise position load areas.

Longitudinal milling of teeth

BRECO® polyurethane timing belts with a longitudinally milled tooth profile are frequently used in combination with sections not being equipped with tension members for applications in the vacuum transport technology. Especially for applications in this field, BRECO® polyurethan timing belts offer a wide range of products. Laying out the tooth profile is significant for CONTI® SYNCHROFLEX polyurethane timing belts, which are protected from running off laterally for instance by bed plates. The processing depth x is indicated as measured from the tooth head.

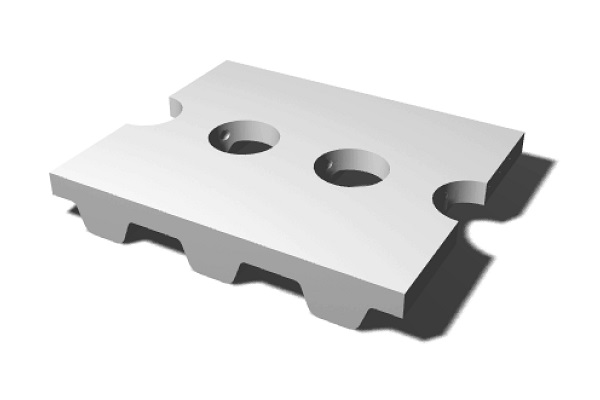

Perforated timing belts

The use of perforated BRECO® polyurethan timing belts is preferred for areas without tension members (to a limited degree also available as BRECOFLEX® polyurethane timing belts) and areas with teeth removed in the longitudinal direction, if they are to be employed as suction belts in the vacuum transport technology. The multitude of design possibilities of BRECO® polyurethane timing belts as vacuum timing belts as well as our extensive experience especially in this field includes the transport of delicate films up to sheet bars of several square meters in size. Aramid tension members are to be used preferable with CONTI® SYNCHROFLEX polyurethane timing belts.